Drying of colloidal suspensions

Directional drying of colloidal suspension can lead to beautiful, complex, intriguing, but hard to predict fracture patterns which are difficult to predict using conventional methods. In this project, we focused on drying of suspension inside capillary tubes.

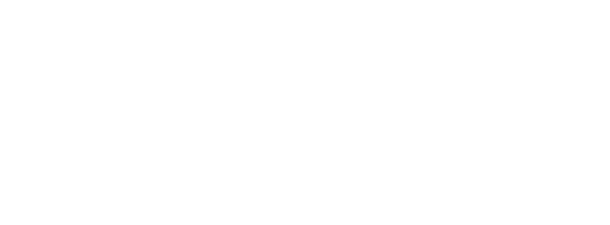

A vertical glass capillary is filled with a colloidal suspension and placed in a controlled temperature and relative humidity environment (Gauthier, Lazarus, & Pauchard, 2007), (Gauthier, Lazarus, & Pauchard, 2010), (Gauthier, Lazarus, & Pauchard, 2010). The liquid is allowed to evaporate only from the lower opening of the tube. As the sample loses water, particles aggregating at the open edge form a growing drained solid porous medium. High negative capillary pressure in the draining fluid generates tensile stresses in the gel. This causes crack formation along the drying direction. The crack pattern can be identified through direct observation in a microscope or by cutting a cross-section of the tube.

Experimental setup and crack pattern

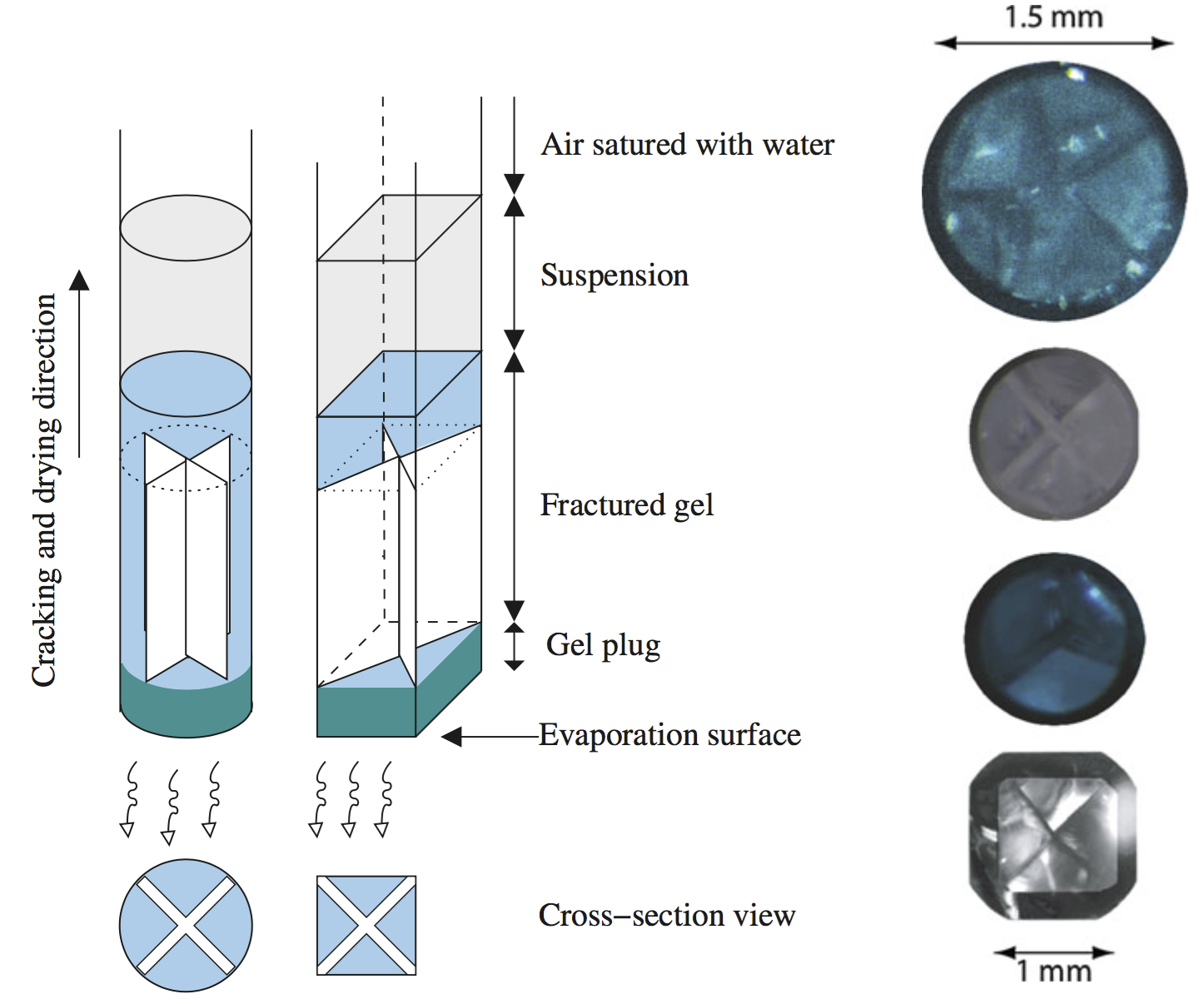

From a modeling standpoint, in some situations, this complicated three dimensional evolution problem can be reduced to a static two-dimensional problem in a cross-section. The complicated loading state can be reduced to a simple isotropic inelastic strain. Using a combination of continuation methods and of a selection principle similar to the backtracking method, we were able to obtain perform validation and verification of the variational model applied to this problem.

When the loading parameter is small (corresponding to slow drying rate), the observed geometry consists of star-shaped cracks, and the optimal configuration can be computed in a semi-analytical way. We were able to recover similar crack patterns without a priori assumptions on their geometry. For higher drying rates, numerical simulations highlight crack pattern with a lower energy than star-shaped cracks.

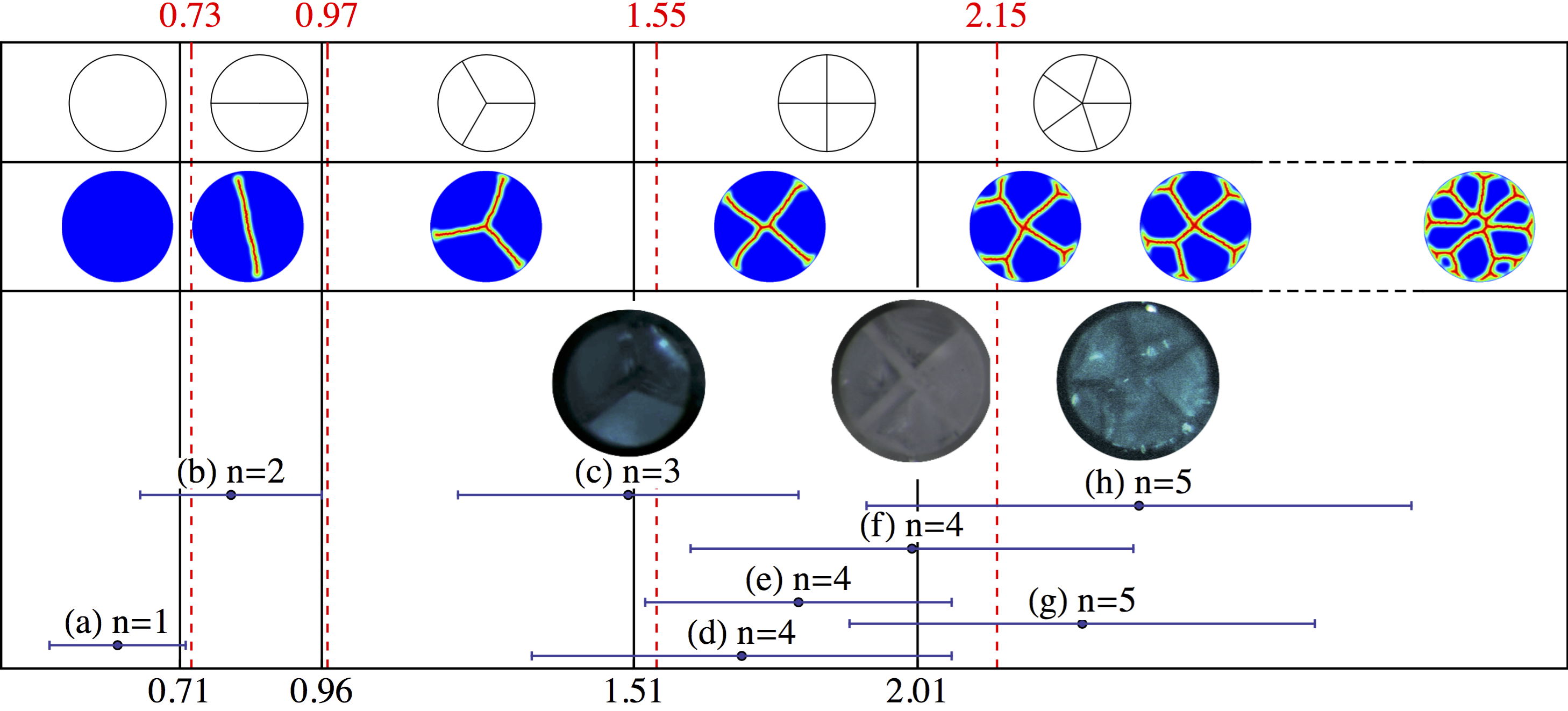

Comparison between Experiments, simulation and semi-analytical solutions from (Maurini, Bourdin, Gauthier, & Lazarus, 2013).

The following figure summarizes the finding of (Maurini, Bourdin, Gauthier, & Lazarus, 2013), by comparing experimental results, numerical simulations and semi-analytical solution.

Comparison between Experiments, simulation and semi-analytical solutions from (Maurini, Bourdin, Gauthier, & Lazarus, 2013).

References

- Gauthier, G., Lazarus, V., & Pauchard, L. (2007). Alternating Crack Propagation during Directional Drying. Langmuir, 23(9), 4715–4718. DOI:10.1021/la063702w

- Gauthier, G., Lazarus, V., & Pauchard, L. (2010). Shrinkage star-shaped cracks: Explaining the transition from 90 degrees to 120 degrees. EPL (Europhysics Letters), 89(2), 26002. DOI:10.1209/0295-5075/89/26002

- Gauthier, G., Lazarus, V., & Pauchard, L. (2010). From 90^∘to 120^∘fracture angles. Europhys. Lett., 89(26002). DOI:10.1209/0295-5075/89/26002

- Maurini, C., Bourdin, B., Gauthier, G., & Lazarus, V. (2013). Crack patterns obtained by unidirectional drying of a colloidal suspension in a capillary tube: experiments and numerical simulations using a two-dimensional variational approach. Int. J. Fracture, 184(1-2), 75–91. DOI:10.1007/s10704-013-9824-5 Download

More pages on this topic

RESEARCH

defectmechanics